Learn about the most recent innovations in cruise ship safety, facts, most common safety issues. This is a cruise ship technology-related survey and is integrated with our articles on cruise shipbuilding, propulsion and health-themed (COVID/Coronavirus and Norovirus). Follows the link to the passenger shipping safety act (in pdf format) on govinfo.gov (US Government's Printing Office website). The document's official title is "Cruise Vessel Security and Safety Act" (issued 2010).

Cruise Ship Safety

Construction techniques concerning cruise ship safety today are far from the methods used for building the notorious RMS Titanic ship. In 1912, marine vessels have been pieced together in small dockyards by teams of skilled men, which was a really labor-intensive affair - and a slow process.

Cruise ship safety regulations

According to the latest cruise vessel safety act regulations, passenger ships must have:

- Navigational aids (echo sounder, AIS, ECDIS, radar), Voyage Data Recorder and DGPS precision position finding equipment. Also communications by satellite, VHF, and GMDSS

- EPIRB (Emergency Position Indicating Radio Beacon).

- Welded and compartmentalized cruise ship construction (including modern fire containment systems). The vessel's bridge must be designed to facilitate the best all-around visibility.

- Enclosed lifeboats and rafts with full crew and passenger capacity (to accommodate all passengers and crew on board, plus spare capacity). Also mandatory are the emergency immersion suites (inflatable life jackets) for all passengers and crew.

- Up-to-date weather forecast system, including hurricane tracks, iceberg locations tracking (also calculating the iceberg's drift pattern), storm warnings.

- Helicopter pad (typically located on the bow of the ship) for emergency rescue and long-range casualty evacuation services.

- Mandatory is also the passenger information (PA-Public Announcement) system, crew training in emergency procedures, safety drills, onboard physician (resident doctor) and nurse.

On most large-capacity ships, lifejackets (life vests for passengers and crew) are stored not in the cabins but at the muster stations, which greatly improves the ship evacuation process.

Muster drill (aka lifeboat drill/safety drill) is a shipboard exercise (conducted by the crew approx 30 min prior departure). It prepares passengers for the safe evacuation of the ship (in cases of emergency) and also familiarizes them with the ship's escape routes.

Cruise safety changed the shipbuilding industry

Modern shipbuilding uses many innovations in construction, such as prefabrication, welding, and computer-aided design. The shift to prefabrication together with the innovations of welding (providing higher quality compared to riveting) have improved cruise ship safety.

Europe was the world's shipbuilding centre in the Titanic era. It was the buyer and employer of raw materials. Shipyards at the turn of century, had moulding areas, platers' sheds, and ironworks, plumbers, joiners, blacksmiths, French polishers, cabinet makers shops, fitting out docks, shipbuilding berths. Most parts of the built were made on site. Europe lost shipbuilding dominance a hundred years later, because of the cheaper Asian shipyards, specifically South Korea, China, and Japan.

After the change in the shipbuilding hub, a change in shipbuilding techniques was inevitable. Today, the biggest part done at shipyards is just assembly, but not pure construction. Contemporary vessels arrive in prefabricated sections at dry-docks only to be welded together. The shipbuilder is likely to assemble several consecutive ships.

Fixing Cruise Vessel's Position

However, maybe the most important progress needed for improving safety through the navigation of cruise vessels was made in the 20th century's last quarter: the GPS (Global Positioning System).

GPS is used by cyclists and hikers along with drivers and merchant ships. In 2010 the GPS and the DGPS ("differential" enhanced version) relied upon positioning of thirty-one satellites, and this fact is remarkable for the global scale and Position-fixing precision of GPS systems. Not dependent on location or weather, they are easier, cheaper, more precise and faster than anything before. DGPS is accurate within 1 sq.meter in optimal conditions.

Satellites also improved communication and cruise ship safety. The Titanic's radio range was just 200 ml (320 km). Today shipboard personnel can remain in touch 24 hours a day with those ashore, no matter in which part of the world the ship is sailing. When the Titanic was created, this was possible only if a vessel was close by, transmitting from one ship to another, and in case the radio officer was at his monitoring station. Titanic's first transmitted distress messages were missed by nearby Carpathia just because her radio officer was on the bridge.

Navigation Bridge hardware evolves constantly. Among the newest equipment are AIS (Automatic Identification System) and ECDIS (Electronic Chart Display and Information System). Ship's AIS allows tracking and identifying other vessels, as well as to be identified by land-based stations and other ships. It also helps officers to track floating objects in order to predict their actions.

The received AIS data (position, speed, course, unique identification) is displayed on separate screens or ECDIS. The Electronic Chart Display has more benefits: access to any chart, automatic chart updating, effective interface with radar/ARPA - automatic radar plotting aid. For a concise review of the marine vessels AIS equipment and how it works, you also can see our cruise ship tracker. The result can be seen at CruiseMapper's global map.

Advances in forecasting and weather monitoring have also enhanced cruise ship safety. This has a key role in routing - the science (and art) of developing best routes for ships based on ship characteristics, weather forecasts, ocean currents, cargo requirements. The main purpose is to find the best balance and minimize fuel consumption and time of transit without placing the ship at risk of crew injury or weather damage.

Marine Design Innovations for Cruise Ship Safety

Design advancements have also improved passenger ship safety. For most of history, the ships' design process was "trial-error". Design innovations were incremental and relatively conservative. Many principles of modern vessels' design were established by the twentieth century. Ship stability was understood largely. Vessels were compartmentalized in order to slow flooding and improve aid evacuation.

Contemporary computers further contributed to cruise ship safety. Computer analysis and modeling replaced tough calculations on structures, hydrodynamics, and stability. When risks are identified, the ship's design can be modified to temper them.

Structure design and hull weren't the only elements that improved drastically over the past century. Bridge innovations also played key role in ship safety. In 1912, RMS Titanic had navigational aids that were few and typical of the period - chronometer combined with Nautical Almanac reference.

The ship's position couldn't be pinpointed precisely during daylight hours because the location was only determined using stars' positions.

The gyrocompass replaced Titanic's compass and finds 'true north', not the magnetic one. It also made autopilot possible. High-frequency radios today allow ships to broadcast distress calls and safety information, contact other ships in proximity, inform port authorities when needed. Depth finders warn modern ships of potential for grounding by utilizing echo-sounding and play key roles for the development of more accurate sea-charts.

Radars obligatory requirement under the International Convention for SOLAS (Safety of Life at Sea) has moreover revolutionized navigation. Watch officers can anticipate obstacles and hazards before they can really see them. This, combined with ARPA to replace manual plotting of ship movements, has improved the speed and accuracy of plotting and also enhanced situational awareness of the officers who keep navigational watch.

The technological advancements have reduced navigation risks radically and have thus improved cruise vessel safety, since RMS Titanic's days. Undoubtedly, there is more to come, as the knowledge of the marine environment is being enhanced further in the future.

MOB (man overboard detection) system

In March 2025 was announced that Zelim (Edinburgh, Scotland-based company specializing in maritime safety technology) implemented its ZOE (the industry's first AI-based man overboard/MOB detection system) on the Ambassador Cruise Line's vessel Ambition.

ZOE employs a combination of infrared and optical cameras, sensors, and advanced software to deliver continuous 360-degree real-time surveillance for the Navigation Bridge officers.

Unlike conventional MOB systems that mainly detect falls, ZOE's AI-driven models are capable of both identifying and tracking overboard individuals.

The integration of ZOE ensures immediate alerts to the Wheelhouse in the event of an overboard incident, with the system maintaining tracking of the individual until rescue operations conclude.

ZOE's significant advantage is the real-time tracking of MOB incidents. Traditional MOB systems often lose visual contact with the drifting individual as the ship progresses, which complicates rescue operations. ZOE utilizes precise geo-location data, enabling bridge teams to coordinate rescue operations swiftly and accurately, particularly under challenging weather conditions or during nighttime.

As of April 2025, ZOE is undergoing trials on Ambassador Ambition to meet ISO 21195 safety standards for MOB detection. The system has already achieved a 96.8% detection accuracy rate from distances up to 337 m/1106 ft during certification tests conducted by Lloyd’s Register.

New cruise ship evacuation system

In March 2016, Viking Ocean introduced a new cruise ship evacuation system replacing the traditional lifeboats. The new high-capacity system represents a lifeboat-liferaft hybrid called "LifeCraft".

The LifeCraft system allows the quick mass evacuation of the ship with guaranteed maximum safety for its passengers and crew. The system consists of the following elements:

- A launching unit (positioned either on deck or hull built-in) contains up to four LifeCrafts, plus stowage and loading stretchers.

- Survival crafts (LifeCrafts) are inflatable and self-propelled vessels with high maneuverability. Each of them has a passenger capacity of 203 and is powered by 4 engines.

- Passengers enter the boats through chutes. Once full, the crew releases the craft and navigates it to a safe location where it waits for the rescue teams.

In November 2018, Viking's LifeCraft was tested in rough sea conditions, with waves up to 50% bigger industry's standard requirements for heavy-weather testings. LifeCraft successfully passed the "Heavy Weather Sea Trials". Sea trials involved launching and testing in extreme weather conditions (high waves and strong winds - up to 18 m/s gusts and waves up to 4,5 m) in the North Sea. The system was launched with the ship cruising at 3 knots (6 km) against the wind, then was simulated a dead ship condition. The LifeCrafts were launched from both sides of the ship. Then the units were tested for 24 hours (controlled drift) in rough seas, resulting in no sustained damages.

Norsafe "Minima-88" lifeboat for passenger ships

In early 2018, the Norwegian company Norsafe AS (lifeboat builder since 1903) presented a newly developed PELB (Partially Enclosed Lifeboat) design for passenger ships. The "Minima-88" lifeboat model is SOLAS compliant, compact (length 8,8 m, width 4,25 m), with capacity 150 people, signal-colored superstructure and white hull.

The cockpit is mid-forward, providing better visibility during embarkation. Cockpit's roof hatch provides vertical visibility of davits (lifeboat cranes). There are two large sliding doors (portside and starboard) for fast embarkation. Seats are on two levels. A steering nozzle provides better maneuverability and increases bollard pull.

Norsafe was contracted by Xiamen Shipyard (China) to build six lifeboats with compatible davits for Viking Line's newbuild ferry (entering service in 2021 on the route Turku-Stockholm.

In 2019, CCL-Carnival Cruise Lines issued a safety briefing video outlining all the fleet's main shipboard safety regulations.

(Survitec) Seahaven inflatable lifeboat

In May 2022, Survitec introduced Seahaven - the world’s largest inflatable lifeboat by max passenger capacity (1060 people). The lifeboat's first test were conducted in December 2021 (Heavy Weather Sea Trials).

Seahaven can be launched from the cruise liner with the push of a button and during the fall it automatically inflates, with a deployment time of just 4 min. Once deployed, the lifeboat can navigate independently (at max speed 6 knots/7 mph/11 kph) for 24 hours.

(Coronavirus) Cruise passenger health and safety issues (temperature screening, social distancing)

During the global Coronavirus pandemic, in March 2020 DeCurtis Corporation (Orlando Florida-based software company that specializes in mobile applications) introduced "DeCurtis Shield". The application is collecting real-time temperature data (from sensors at the facility's entry and exit points) and also uses an online health database for tracking and locating at-risk people.

DeCurtis Shield collects and stores basic health parameters using facial recognition and thermal mapping technologies. The information is provided from hardware installed in standalone kiosks throughout the cruise liner.

In mid-May 2020, Rescompany Systems LTD introduced a thermal screening system for cruise companies. The real-time health screening process starts at home (via mobile apps) which allows pre-cruise registration, medical screening, documents update. Rescompany's terminals use onboard thermal imaging cameras (with facial recognition capabilities) that repeatedly scan passengers and crew when they pass through checkpoints positioned at key locations ashore and onboard.

In September 2020, the company SICK (specializing in intelligent radar sensors) announced a solution for cruise ships based on its 3D-LiDAR (model MRS1000) combined with SensorApps (SICK's PeCo/PeopleCounter). SICK's sensor solutions don't use/share personal information but only count people (in both open and closed shipboard spaces) to ensure keeping the recommended social distance. The sensors identify only people (objects remain hidden) and also determine directions of movements. SICK's technology can also be used to protect select areas from unauthorized access as motion profiles (number, direction, speed) of even entire groups can be in real-time recorded and analyzed.

Air Quality on Cruise Ships, Pollution

In January 2017, the German Environmental Association NABU (Naturschutzbund Deutschland) issued a survey on air quality onboard cruise vessels. The survey warned that on a larger-sized ship it's more likely passengers to inhale polluted air than a fresh sea breeze.

Onboard measurements of actual air quality onboard were way worse than expected. They were done by cover French TV journalists (from France 3 channel) conducted on a Mediterranean-based cruise ship leaving from Marseille.

Measuring results show that shipboard passengers are exposed to high concentrations of harmful substances, the levels of which surprised even the environmentalists. After the ship left Port Marseille, air pollution was measured roughly 200 (TWO HUNDRED) times that of an urban street during heavy traffic. Besides fine dust and soot, burning large quantities of marine diesel and heavy oil also produced high doses of nitrogen oxides and heavy metals.

Most of the largest cruise line companies have done in recent years significant fleetwide upgrades to their older ships. Among the newly installed technologies are the scrubber systems (aka Chemical Scrubbers). These are expensive air pollution control units used to remove some particulates and gases from the ship's exhaust streams. However, statistics show that 4 of 5 vessels are not equipped with an exhaust gas cleaning devices. Since modern technical solutions to reduce particles and NOx emissions are long present on the market, not implementing such technologies is largely due to greed. It cost money to install them and furthermore requires the shipowner to use more expensive fuel.

The European Lung Foundation (ELF) recommended several years ago that travelers with chronic respiratory diseases should only stay only on certain parts of the ship's open decks to avoid breathing in the exhaust. At the same time, the World Health Organization (WHO) concluded that marine diesel exhaust is just as carcinogenic as asbestos. The ultrafine particles can get into the smallest pulmonary alveoli and from there into the bloodstream.

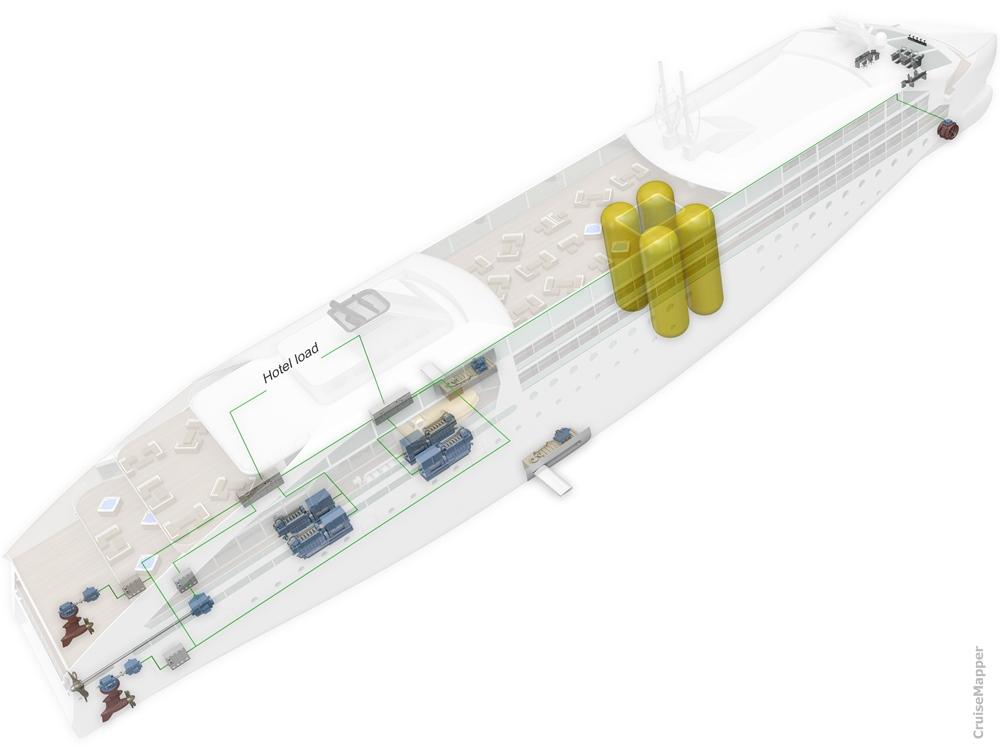

In June 2015, Carnival Corporation contracted the Italian shipbuilder Fincantieri for 4x LNG-powered ships with the industry's largest passenger capacity. This was part of the order with Meyer Werft and Fincantieri for a total of 9 newbuilds to be delivered in 2019-2022. The four units became industry's first LNG (Liquefied Natural Gas) powered vessels using LNG in their hybrid engines. The gas is stored onboard and used to generate all the electricity. The new ships' engines are not exclusively LNG-powered, but dual-fuel (capable of burring both liquid marine fuel and gas). This design is for saving onboard space (reducing fuel storage space that is required).

The new fuel eliminates all the bad emissions - soot and sulfur oxides. In April 2016 MSC Cruises announced its contract with STX France for up to four LNG-powered ships with GT over 200,000 tons each. For comparison, the Oasis of the Seas is 225,000 GT tons. The new MSC ships have 5400 passengers capacity at double occupancy each. The first one is scheduled for delivery in 2022. Its power plant will be based on a new prototype engine.

In November 2016, Port Barcelona presented its "Air Quality Improvement Plan" - an initiative aiming to reduce bad emissions from port activities. The document involved 25 actions rolled out in 53 operations. Among the most representative actions are promoting the LNG fuel (liquefied natural gas) as an alternative for both marine vessels and road freighters. The policy offers discounts for cleaner ships and replacing the port's service fleet with electric vehicles. According to statistics, port activities produce 7,6% of the city's average NOx concentrations annually and 1,5% of the fine particulates. Promoting LNG-powered ships, terminal machinery and trucks are one of the plan's highlights. LNG fuel cuts NOx emissions by 80% and eliminates sooth, particles and SOx emissions. The environmental discounts are on port fees. Currently, the law allows a max 5% port fee discount for environmental reasons.

Starting July 2, 2018, the Norwegian ferry and cruise shipping company Hurtigruten implemented fleetwide a policy for not using any single-use plastic products. The list of banned products includes plastic-made bags, straws, cups, cutlery, toothpicks, aprons, stir pins, drink mixers, coffee lids. The decision made the shipping company world's first "plastic-free". It is estimated that 15 tons of plastic enters into oceans every minute of the day, ranking plastic pollution the world's single biggest threat to the oceans. Hurtigruten's ban of single-use plastics was also imposed on all hotels, restaurants and other establishments contracted by the subsidiary company subsidiary Hurtigruten Svalbard for the land-based operations on Svalbard islands.

IMO's ferry safety video 2018

At the end of June 2018, IMO (International Maritime Organization) officially released a 1-min animated video about safety on ferries. IMO's video is shown in all major ferry port terminals and on national TV channels in the Asia Pacific. The video was commissioned following several IMO-sponsored discussions on ferry safety. On those forums, overloading (with cargo and cars) and overcrowding were highlighted as common problems for passenger ships navigating inland waterways, coastal and inter-island routes.

Domestic ferries in the region are often the only possible (affordable) means of transportation in island countries. IMO's ship safety video was provided for free to all national maritime authorities in the Asia Pacific.

CLIA's Cruise Passenger Bill of Rights

The industry's guarantee for customer service and ship safety is called "CRUISE PASSENGER BILL OF RIGHTS" and was approved by CLIA (Cruise Lines International Association) on May 22, 2013. All CLIA members agreed to Bill's provisions, which became immediately effective for US passengers purchasing cruises on CLIA member companies in North America, regardless of the itinerary.

Although Bill's provisions (including the requirement for employees' training for emergencies) have been practiced for years, this list makes cruise lines' obligations clear to their customers. The Bill further informs passengers of the cruise industry's commitment to their comfort and care. By adopting formally industry practices into the Cruise Passenger Bill of Rights, CLIA demonstrated further consistent practices and showed commitment to continue delivering the highest standards in all areas. The latest industry mechanical failures and high-profile accidents left potential customers wary of booking a voyage.

CLIA's Board of Directors also approved the adoption of the Bill detailing CLIA members' commitment to passengers' comfort, care, and safety. CLIA submitted the Bill to IMO (International Maritime Organization), requesting formal global recognition, as well as applicability under IMO authority over the international maritime industry. CLIA and its members actively communicate the Bill of Rights to cruise ship passengers and the general public. CLIA and all member companies posted the Bill on their websites and provided materials for communicating the Bill to prospective and current customers, as well as to nearly 14,000 travel agents globally.

What is CLIA (Cruise Lines International Association)?

CLIA is the largest in the world cruise industry association, with representation in Europe, Asia, Australasia, North and South America.

CLIA represents travel agents' and cruise lines' interests before legislative and regulatory policymakers.

CLIA is engaged in research, marketing communications, and travel agent training to promote the desirability of cruises with a huge number of travel agent members.

"CLIA Executive Partner and Associate Member" program include leading providers of services and supplies that help member companies to provide environmentally-friendly and safe vacation experience for a huge number of travelers each year.

For information about CLIA and the member travel agencies and cruise lines - www.Cruising.org

In addition to the Bill of Rights, CLIA's other proactive initiatives focused on passenger comfort, care and safety include:

- Establishment in 2012 of Operational Safety Review, which resulted in the adoption of ten safety-related policies, submitted to IMO;

- Launch in March 2013 of Preparedness Risk Assessment in order to address and review excess associated with power systems which provide essential services in main power loss' events;

- Successful completion in April 2013 of an emergency multi-day drill involving authorities from Bahamian and US governments, led by USCG (US Coast Guard).